Molds are various molds used in industry to obtain products by methods such as injection molding, blow molding, extrusion, die-casting, forging, smelting, and stamping. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. Known as the "mother of industry". It is widely used in the forming process of punching, die forging, cold heading, kneading, powder metallurgy parts pressing, pressure casting, and compression molding or injection molding of engineering plastics, rubber, ceramics and other products.

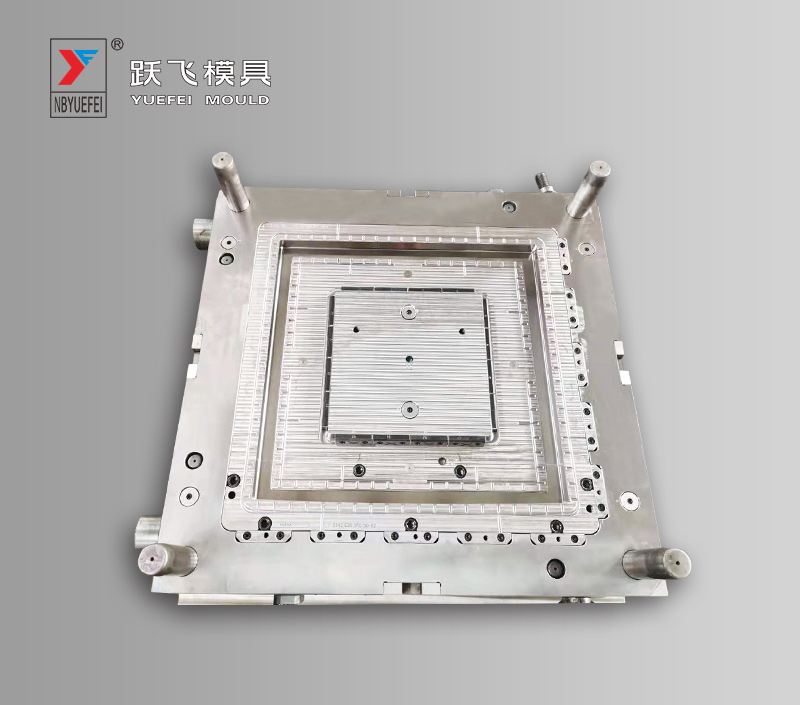

There are many varieties of molds, which are divided into processing metal molds, processing non-metal molds, and processing powder molds according to the processing goals and processing techniques of the molds. In the production of a mold, in addition to the mold itself, it also needs to be composed of a mold seat, a mold base, a guide device, and a part ejection device. Generally, except for the mold itself, other parts are all common models.

A mold, in short, is a model. Products in the industry are produced according to this model. Therefore, the importance of molds is inexplicable. Most daily necessities in life cannot be separated from molds. Molds play a role in life. To an irreplaceable role.

The role of the mold:

(1) The mold industry is an integral part of the high-tech industry. For example, the planning and production of integrated circuits in the field of high-tech skills cannot be done without a fine progressive die for the lead frame and a fine integrated circuit plastic film; the manufacture of the computer case, plug-ins and many components must also have fine plastic molds And fine stamping dies; digital electronic products (including communication products) can not be developed without fine dies.

(2) The mold industry is an important category of high-tech industrialization. The improvement of mold making skills and the improvement of mold industry skills are inseparable from the grafting of high-tech skills.

(3) The mold industry is an integral part of the equipment industry. As a basic process equipment, molds have an important position in the industry.

(4) The importance of the mold industry lies in the fact that the five pillar industries of the national economy-machinery, electronics, automobiles, petrochemicals, and construction all require the development of the mold industry to respond to them to meet the needs of the five pillar industries.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche